Technologies

Progress, not only in our products but also in the materials we use and a resource-saving production technology, is an ongoing challenge for us that we meet every day.

The greatest visible successes to date are associated with the brand names RE-Wood, RE-Plastic and MAG-Pap.

But also the use of product cartons instead of plastic foils as packaging, protective paper of cover materials as packaging material, energy-saving compressed air compressors and a modern cooling system for our injection molding machines are just a few examples of our daily implementation.

We always inform about this in our newsletters and on our website.

RE-WOOD

This brand name is our ecological alternative to plastic!

SUSTAINABLE & POLLUTANT FREE

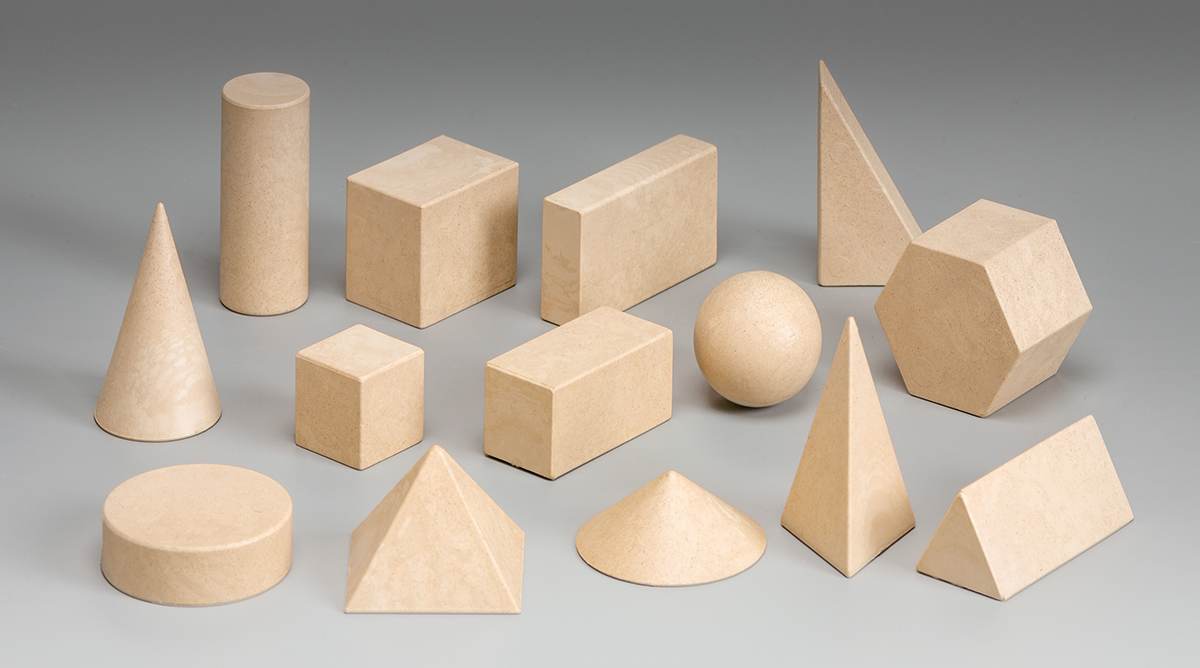

Our RE-Wood material is produced in a resource-saving way from shredded wood residues, which are a waste product of wood processing in German production facilities, and a recycled binder in a ratio of 80:20.

RE-Wood consists of 100% recycled and natural materials and is certified with the PEFC seal. Products made of RE-Wood are stable, light, saliva proof and they have a high level of safety in use.

STABLE

EASY

SALIVA PROOF

For us, RE-Wood is not only the material from which we manufacture a large part of our products, it is a forward-looking technology and our pride and joy.

More than 10 years of development time have gone into this idea and our requirements were high.

We wanted to create a sustainable product and the material we wanted to invent should

… be available at any time

… consist of regional raw materials

… be produced in an environmentally friendly way

… not contain harmful substances

… correspond to the mechanical properties of the previous plastic material

… be processed on our machines

… guarantee a long service life

… not be too expensive

Phew, the bar was high!

But after 10 years of development and in cooperation with renowned research institutes like the Fraunhofer Institute, we found a way to reuse wood waste in an ecologically sensible way.

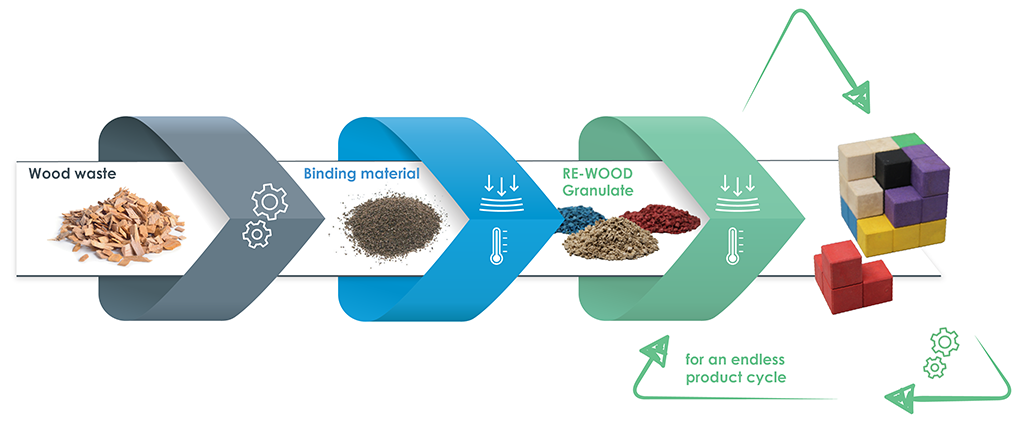

Basically, as with all good inventions, it was quite simple: The basic material consists of two waste products, which we breathe new life into. 80% ground wood residues from PEFC-certified sustainable forest management and 20% binder. These two components are combined into a wood-like mass using heat and pressure.

In order to be able to process this compound on normal moulding machines, the raw material is crushed to granulate size. What sounds so simple, has its pitfalls in the production and so far no other manufacturer has succeeded in realizing a comparable material.

A pro pos pitfalls... every invention and product development has challenges and some is indispensable. It doesn't work without the other.

Biodegradation and sustainable disposal

With RE-Wood, for example, we have invented a material that is completely degradable in its composition, or compostable by mushrooms and bacteria, if it is allowed to decompose long enough.

Long enough means about 25-80 years, the biological degradation takes place similarly slowly as hardwood. This slow degradation process has the great advantage that RE-Wood articles are safe to use, insensitive and robust for a long time under all environmental influences. They can even be cleaned several times in dishwashers.

But these quality characteristics also ensure that disposal in organic waste is not possible, as composting plants and their disposal guidelines require a degree of decomposition of 95% within 6 weeks. However, RE-Wood cannot and should not achieve this, as otherwise the safety of use and durability would suffer.

Thus, we have developed a material made of recycled materials, which in case of emergency can only be disposed of in the residual waste.

But in the best case RE-Wood is not disposed at all. It can - no matter how old - always be 100% reused. From old we make new - over and over again without losing the good properties.

That is why we appeal to our customers: Help us not to dispose of RE-Wood, but to reuse it. Send us back old and no longer used RE-Wood articles.

The smell

As described above, RE-Wood consists of 80% ground wood residues and is heated to a high temperature during the manufacturing process. During this heating process, natural, non-toxic degassing occurs, which leads to a low smell formation. If the RE-Wood article is shipped from us without long intermediate storage, the non-toxic residual degassing takes place in the packaging. After a few days, the associated smell will have dissipated. And we have deliberately decided against additionally added fragrances and want the material to be as pure and natural as possible. With the accompanying smell of highly heated wood.

RE-PLASTIC

All plastic parts that we produce for our teaching and learning aids as well as drawing instruments are made of our sustainably recycled plastic RE-Plastic.

For RE-Plastic we use 100% recyclable polystyrene from "Post Consumer Production " post-industrial waste, which we recycle on site and return to production. Because RE-Plastic can be recycled over and over again, we are able to maintain this recycling loop steadily, effectively and responsibly.

RE-Plastic is absolutely equivalent in quality, appearance and feel to new plastic granulate. The use of RE-Plastic is a sensible use of resources, ecological and CO2-neutral > this is realized environmental protection without loss of quality!

MAG-PAP

MAG-Pap is a high-quality, magnetic 2-component material. The top side consists of a 1mm thick cardboard made of 100% recycled material, which is bonded with a waterproof, abrasion-resistant printing sheet. This layer is bonded to the underside with a full-surface and 0.5mm thick magnetic film. MAG-Pap is ideal for classic blackboards, whiteboards, smartboards and presentation boards.